Real history of the discovery of XRF

Barkla’s Pioneering Observations in X-Ray Physics

- The discovery of X-rays by Wilhelm Röntgen in 1895 transformed the trajectory of physical science, triggering an international race to decode the behaviour of electromagnetic radiation interacting with matter.

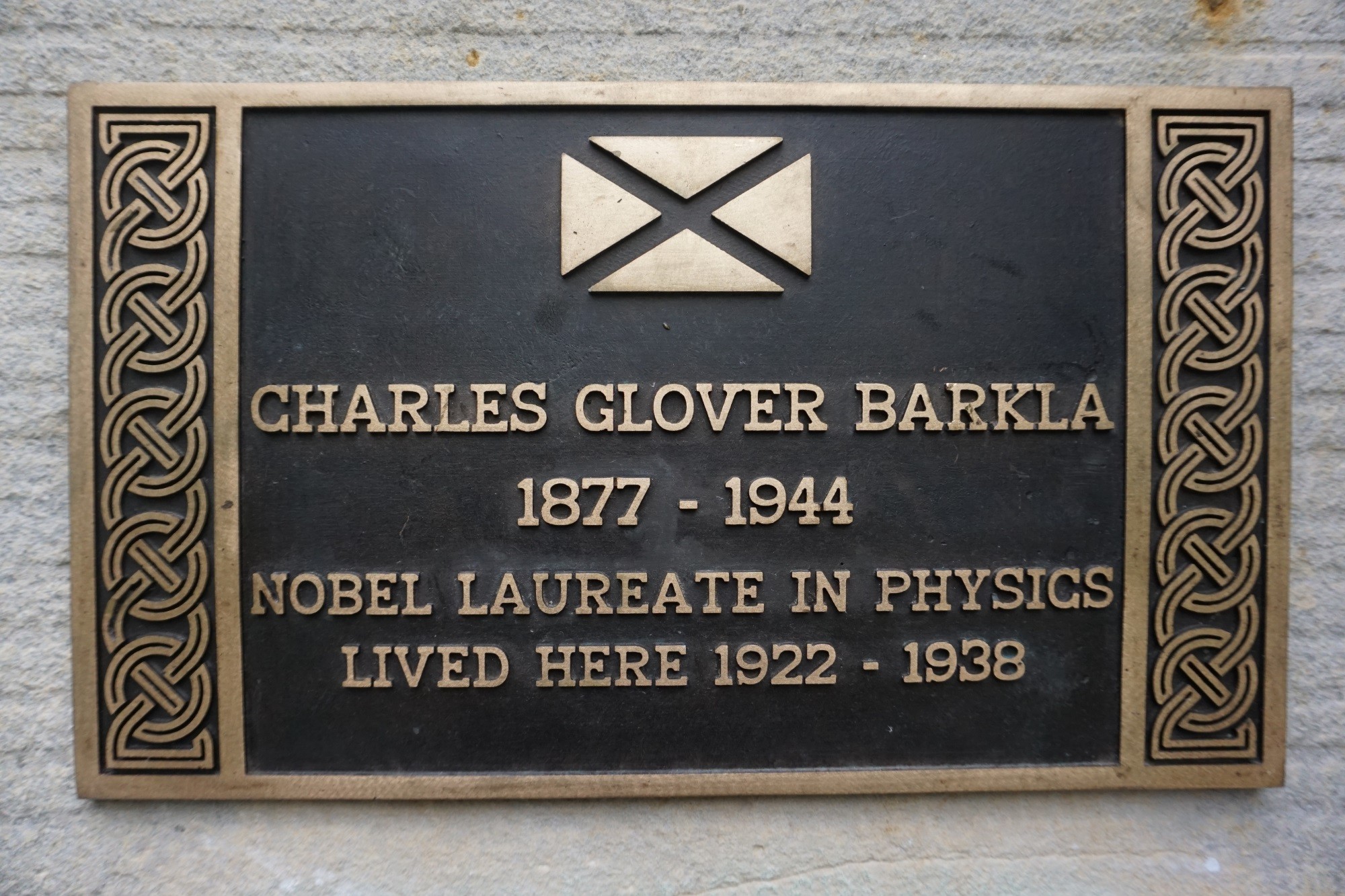

- British physicist Charles Glover Barkla, a specialist in electromagnetism and atomic theory, emerged as a leading figure in early X-ray research, particularly in understanding secondary emissions from materials exposed to X-rays.

- In the early 1910s, Barkla began rigorous experiments exploring how various elements responded to incident X-ray beams.

- During his studies, he identified a crucial phenomenon:

- When struck by high-energy X-rays, certain elements emitted secondary radiation – a set of X-rays distinct in wavelength from the original beam.

- This was not mere reflection but a unique, element-specific re-emission of X-rays.

The Origin of X-Ray Fluorescence (XRF)

- Barkla termed this behaviour “X-ray secondary radiation,” though it would later be formalised as X-ray fluorescence (XRF).

- The defining insight was that the emitted radiation patterns were distinct for each chemical element.

-

- Iron emitted one characteristic energy profile, copper another, and so on.

-

- This breakthrough established XRF as a method of elemental composition testing, revolutionising how scientists and engineers could identify materials without damaging the sample.

Applications of XRF in Precision-Driven Industries

Today, Barkla’s findings power a wide range of technologies used in high-precision material analysis, especially:

- XRF analysers used in metallurgy, mining, and chemical processing

- Field-ready portable spectroscopy devices for on-site elemental verification

- Advanced non-destructive testing equipment in aerospace, automotive, and infrastructure sectors

- Real-time material verification systems in production lines and quality control labs

Industrial Impact and Analytical Reliability

The use of XRF has become a gold standard in industries requiring:

- Fast, repeatable, and quantitative elemental analysis

- Regulatory compliance in environmental and food safety inspections

- Supply chain verification to authenticate metals, alloys, and composite materials

- Modern instruments – from benchtop systems to portable XRF analysers—combine Barkla’s foundational principles with AI algorithms, cloud integration, and automated data processing.

Legacy and Forward Outlook

- Charles Barkla’s work didn’t just explain a scientific effect – it introduced a tool that continues to shape how we explore and verify the composition of the physical world.

- From material certification in critical industries to rapid on-site inspections, XRF remains indispensable for professionals seeking accurate, real-time insights into elemental structures—all without sample destruction or delay.

Reference

All are hyperlinked in the text

Read more

https://basicprinciple.online